Successful management of specifications (packaging, product, materials, etc) is a critical component of any product’s lifecycle. Businesses that are using spreadsheets or other manual methods of organizing, routing and distributing their specifications typically come to a point when automating workflow becomes an option worth investigating. Whether you find your employees are sometimes working from the wrong version of a spec or suppliers aren’t being notified when a new spec becomes effective, there are many efficiencies to be gained when using a manual specification management process. A specification management system can provide transformative benefits for your product lifecycle by streamlining internal processes and enforcing data standards across your company, ensuring quality and compliance.

What is the best method of making sure your specification workflow is running efficiently? Let’s take a look at 5 of the best tips to optimize the workflow of your specifications.

1) Set specification standards for using structured data

Structured data refers to any data that resides in a fixed field within a record or file. This includes information contained in relational databases and spreadsheets. Data of this type within your specification management system allows for controlled, approved values; things like dropdown lists, checkbox lists, text, calendar, formulas, English/metric converters, grids required fields, and character limits.

You know best what materials your company uses and what units of measurement are acceptable. If your employees can make any type of data entry into these documents, your information will be far from uniform. When data that does not match up, usage of the spec can be extremely confusing once it begins being utilize on the manufacturing floor. Ensuring that your electronic forms have specific restrictions in terms of what exactly can be written and placed within the document make the specification process much smoother once this data makes it down the workflow pipeline within your company.

2) Define a document hierarchy

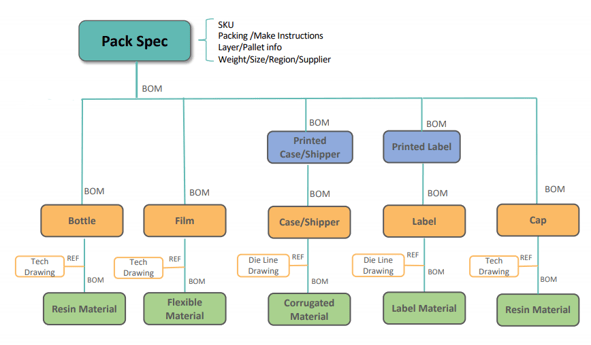

When you start to use a specification management system, it is very important for your organization to understand the purpose of each type of document, and their application in the documentation hierarchy. There are different types of documents that help make a company run smoothly. Spec hierarchy can include Packaging Specifications (SKUs) which include the Bill of Materials (BOM), printed components, component (common specs), masters, materials and even the related content such as procedures, work instructions, test methods, and drawings.

Here is an example of a hierarchy structure:

This diagram shows the packaging specification for a hypothetical shampoo bottle with a four tier hierarchy, making use of common specs which store data such as weights and dimensions, test methods, etc., leaving the printed component level to store key info that differs for each market’s consumer unit such as brand, variant, pack size, market and language. At the top of the hierarchy is the Packaging information, containing palletization, master data and brand, variant, pack size, etc. A well organized and defined hierarchy supports the distribution, maintenance and understanding of your individual documentation,

3) Design and implement a workflow that satisfies these questions:

- Who in your company is allowed to create specifications?

- Who in your company is allowed to see specifications as various stages of the development/approval process?

- Does your company require peer review?

- Can those assigned as peer reviewers edit or simply provide commentary?

- Who is allowed to approve a document?

- Do you have a minimum number of approvers?

- When you build the relationship in the hierarchy, do you require that if a subordinate specification is revised, all parents should be revised?

Without addressing these questions, the workflow will end up disconnected. Employees who are not meant to review certain specifications may be granted incorrect responsibilities and documents may end up in the wrong hands. However, accurately answering these 7 questions will guarantee that your workflow is thoroughly formatted and that your employees understand their role in the process, saving you time and confusion as the workflow progresses.

4) Consider distribution of your specification notifications

Another important question to ask is who should be notified when a revised specification becomes effective, superseding the prior version? Staying updated on changes happening in your document management software is very important, especially if you are dealing with specifications, important work-related documents, and tasks related to these documents. However, users cannot be expected to work constantly in their document management software to manually monitor these changes.

Thus, email notifications become extremely important within a specification management system. Using email notifications, the people who are involved with a specific document know when changes are being made within the system. This does not have to remain limited to your employees. Specification management systems allow notifications to be sent out to your suppliers and vendors, helping you further streamline your workflow. Even with a built-in email mechanism, if you accidentally choose to send email warnings to the wrong people, important contributors could be left out entirely and miss important updates. Therefore, taking the time to set up an email notification system and carefully choose which team members receive these notifications is extremely important in keeping your workflow process running efficiently without any mistakes.

5) Define Reporting Requirements

The last tip you should be sure to follow is the process of defining your company’s reporting requirements. Different industries and types of businesses require different types of reporting. Most of these requirements involve full audit reports regarding who changed things within a document and when. These questions are important as they give your company the ability to solve very important business problems such as:

- Why are approvals taking so long?

- What stage is holding up a process?

- What is the average time from when you create a specification to when it’s effective?

- What members of our team/suppliers/customers have specifications been sent to?

When setting up your specification workflow, it is important to define the exact requirements your software will use when looking at changes being made to your documents. If your company runs into a production issue down the line, you will be happy you have the ability to go back and pinpoint the exact cause of the problem. A thorough reporting plan will decrease internal frustration, reduce the length of your processes, and most importantly, save you money.

Specification management can be complex. But if your company follows these 5 tips when configuring your specification workflow, you can rest assured that your processes will run efficiently.

If you are looking for an organization to help you configure your specification management process, DocXellent can help. We are glad to advise you on how you can accomplish your goals and demonstrate how our specification management application can maximize your company’s efficiency. Contact us today.